60% Smaller Footprint,

30% Faster Cutting

"The CNC That Defies Tradition"

Taurus Craco Machinery is now Canada’s distributor for Muratori’s Ranger Vertical CNC, the first router designed to shrink your footprint while boosting productivity.

Book a free onsite efficiency audit to discover how the Ranger can transform your operation. Our CNC experts will visit your facility to:

✔ Measure your exact space/labor savings with the Ranger

✔ Analyze your material workflow for optimization

✔ Provide exclusive launch pricing

Limited spots available – Schedule your no-obligation assessment today.

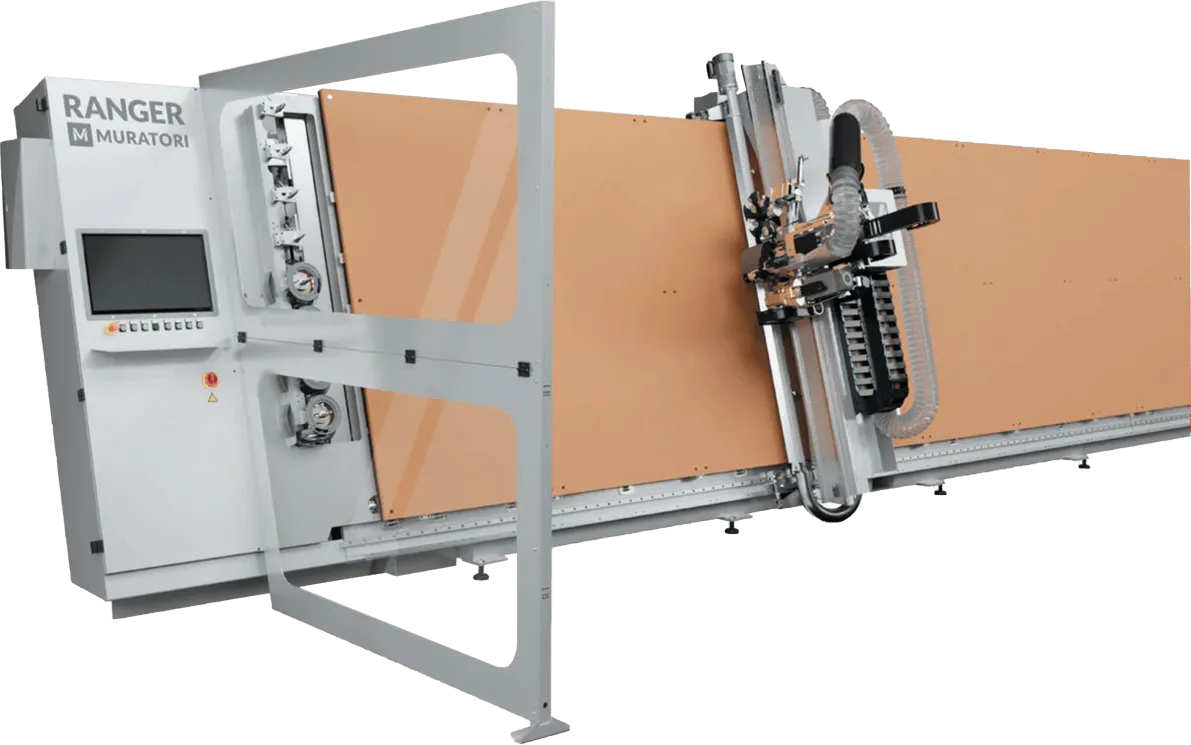

Ranger CNC

Precision Without the Mess: The Vertical CNC That Cuts, Drills & Mills Safer

RANGER is the Panel Router with Vertical Table for high-speed panel cutting, drilling and milling.

Ranger is a machine designed and equipped to process panels made of different materials, such as solid aluminum, ACM, HPL, fiber cement and plastic, which are used in a variety of sectors, including architecture, industry, transport, interior design and visual communication.

The verticality of the worktable, its solid construction and patented automation systems are just 3 of the main features of Ranger that ensure increased safety, efficiency, cleanliness and quality during processing.

Play video of Ranger machine in action!

Tired of Your Bulky, Slow CNC Router?

Save 40-60% floor space: Vertical design fits where horizontals can’t

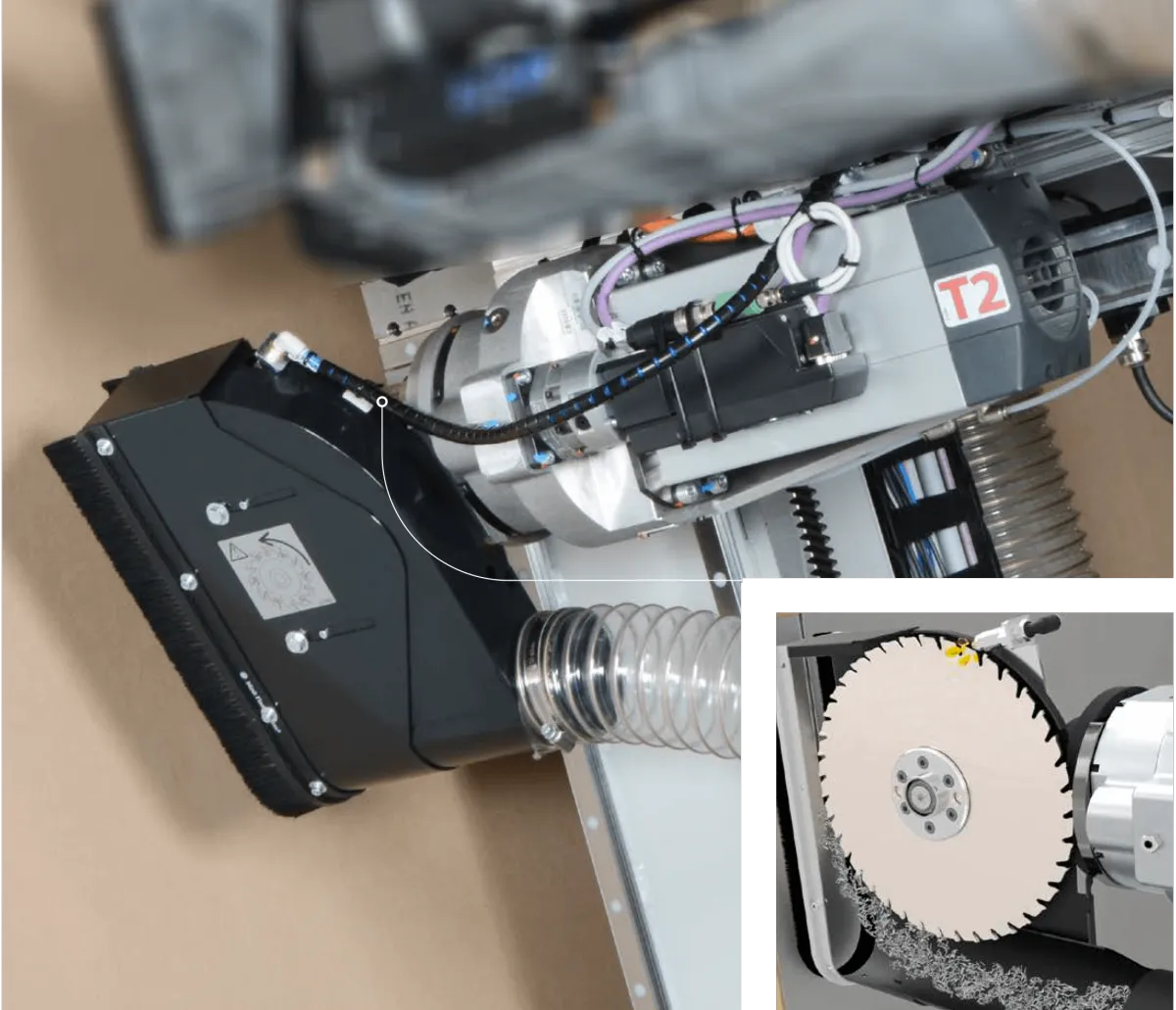

Cut 2-3X faster with optional Indexing saw blade (vs. router bits)

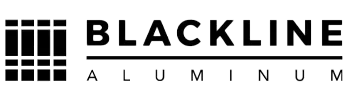

Reduce labor costs: Patented auto-loading eliminates manual sheet handling

Why Settle for an Outdated CNC?

Smaller footprint = Lower facility costs

Engineered for diverse materials: From lightweight to dense industrial panels

Built-in automation: No need for costly retrofits later

Workable materials:

Melamine and Plywood, Aluminum Honeycomb, Polyurethane, Polycardboard, PMMA, Plexiglas, Acrylic, Fiber cement, Composite Steel, Forex, Polycarbonate/Lexan, Polyester/polyzene, HPL, Solid Surface (Corian)

Onsite Efficiency Assessment

Available dates upon request

Your assessment includes:

Free space/labor savings assessment

Tailored workflow recommendations

Custom material compatibility review

PARTNERS

Trusted by Top Manufacturers

Join the manufacturers who’ve already revolutionized their workflow with vertical CNC technology.

Vertical CNC Router Specifications

Space-Saving CNC Machine Design

60% smaller footprint

than traditional horizontal CNC routersSame worktable area

with vertical compact design

Ideal for small workshops

or crowded production floors

High-Speed Panel Processing

Optional Indexing saw blade

for 10X faster when cutting linear geometry vs. router bitsAutomatic tool changer

(8 positions) – reduce downtimeCamera mark recognition for precision alignment

Safety & Clean Operation

Photoelectric safety cells – operator protection

Self-cleaning vertical table

– chips fall away automaticallyReduced manual handling

– ergonomic loading/unloading

Get the Full Technical Catalog

Download complete technical specs including dimensions, power requirements, material compatibility and real-world case studies showcasing 60% space savings.

30+ Years of CNC Expertise

Drawing on decades of Canadian manufacturing experience to optimize your operation.

Lifetime Local Support

Our Canadian-based Taurus Craco Machinery support team – just one call away.

Free Onsite Training

2 days of hands-on training tailored to your materials.

FOLLOW US

COMPANY

CUSTOMER CARE

LEGAL

Copyright 2025. Taurus Craco Machinery Inc.. All Rights Reserved.